OTC Industrial Technologies Case Studies

Our case studies highlight real-world success stories where our innovative solutions have helped businesses improve efficiency, reduce operational costs, and enhance equipment reliability. From custom air supply systems and filtration solutions to data-driven automation and equipment monitoring, OTC delivers measurable results across diverse industries. OTC is commited to driving customer success through tailored, high-impact industrial solutions.

Air Supply

Food and Beverage Ammonia Compressor Repairs

A longtime customer in the food and beverage industry worked with the OTC team for motor repairs and purchases. Over that time, the company had come to rely on OTC for emergency repairs.

OTC and DIRECTAIR® Save Furniture Company $75,000 in Annual Energy Costs

A furniture company had six air compressors operating in three separate plants. Each machine was running only partially loaded. Although two of the plants were connected, the combined air compressors were operating as two separate systems.

DIRECTAIR® Saves Automobile Parts Manufacturer $200,000 in Energy Costs

A manufacturer was running two air compressors at 60% capacity and struggled with extremely high maintenance and energy costs.

EV Battery Manufacturing Facility Relies on DIRECTAIR® from OTC

The growth of electric vehicles comes with a variety of opportunities and challenges. The need for high-quality EV batteries is a challenge faced by automakers, and as it’s a relatively new technology, there isn’t an exact blueprint for success.

OTC Provides Emergency Relief for Critical Medical Gas Supplier

In Puerto Rico, a large facility producing gases for the medical industry experienced a critical failure. The main compressor at this location stopped working, and production came to a sudden halt. Without a compressor in place, the operation could no longer produce life-saving resources.

OTC Prevents Critical Downtime for a Major Gas Company

Faced with the critical failure of two massive air compressors, a major gas company’s entire operation had to shut down. During this downtime, the company was losing thousands of dollars each minute. These compressors were massive and not easily replaced.

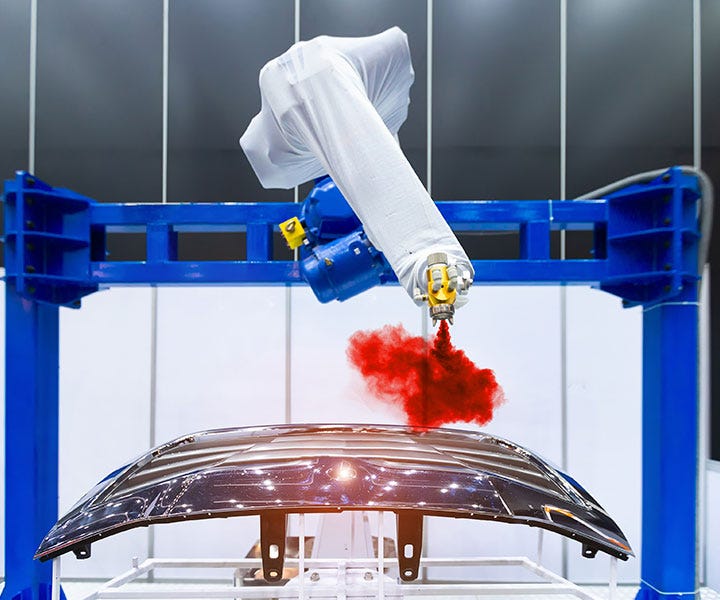

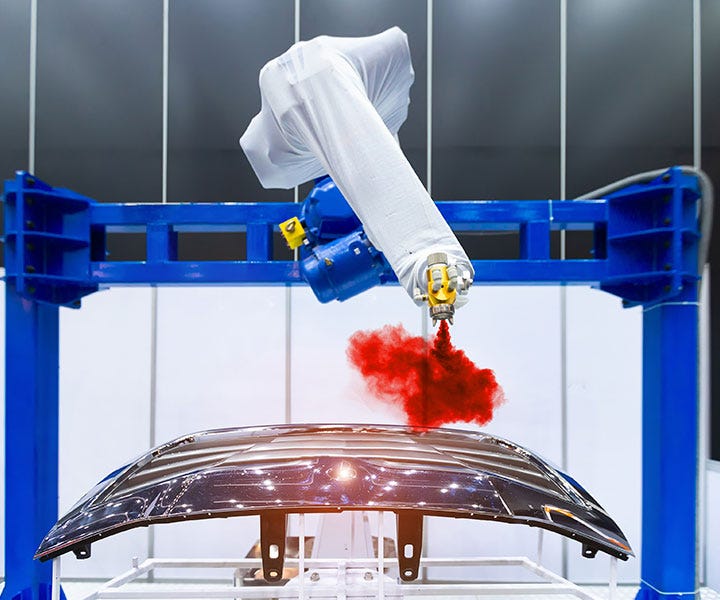

Finishing & Dispensing

Custom Filtration System Streamlines Production and Reduces Operational Costs

A prominent manufacturer of automotive parts and decorative trim solutions faced persistent challenges in its finishing department. An unreliable filter setup, compounded by frequent filter replacements, escalated both costs and disruptions to core operations.

Improved, Custom Filtration Solution for a Tier 1 Automotive Supplier

A Tier 1 automotive supplier encountered persistent complications with its filtration setup. The existing system failed to align with strict airflow requirements, resulting in frequent filter replacements, rising costs, and periodic disruptions to production.

Reduced Costs Through a More Refined Filtration Strategy

An original equipment manufacturer (OEM) specializing in interior automotive components faced exorbitant expenses due to the daily replacement of its primary filter in a paint booth filtration system. Recognizing the need for a more cost-efficient approach, OTC Industrial Technologies offered a comprehensive, innovative solution that substantially reduced both material and labor costs.

Eliminating Component Failures and Downtime for a Manufacturer

A musical instrument manufacturer, one of the leaders in the industry, saw frequent downtime due to component failures within its finishing systems. For this manufacturer, a single line going down for an hour was $100,000 in lost revenue.

OTC's Custom Solution Quadruples Filter Life Expectancy

Finding the source of inefficiency within an operation isn’t always easy. Many companies experience these inefficiencies and write them off as part of doing business. However, OTC Industrial Technologies is not satisfied with this approach and wants our clients to get the most value out of every aspect of their operations.

Industrial Automation

Eliminate Scrap Rate for Auto Parts Manufacturer

A supplier and all-around manufacturer of pressed parts for the automotive industry struggled with a high scrap rate of non-conforming parts. This meant not only increased waste and higher production costs, but also extensive quality checks on every run.

Equipment and Automation Downtime Causes Safety Concerns

A supplier and all-around manufacturer of pressed parts for the automotive industry struggled with a high scrap rate of non-conforming parts. This meant not only increased waste and higher production costs, but also extensive quality checks on every run.

Rotating Equipment

How a High-Volume E-Coating Facility Reduced Gusher Pump Downtime with OTC’s Data-Driven Equipment Monitoring Strategy

A manufacturing facility was experiencing frequent pump failures in their production line, particularly with Gusher Pumps used in E-coat and chemical parts wash processes. These pumps operate continuously in a harsh chemical environment with minimal maintenance, resulting in costly downtime whenever a pump needed replacement.

OTC Assists with Revolutionary Thermal Hydrolysis Project

Thermal hydrolysis is a fascinating and innovative technology. This process transforms biological waste into usable biomass and gas that can feed directly into natural gas pipelines. More popular in Europe, there are currently fewer than 10 plants installed in the United States.

Boiler System Analysis at Food and Beverage Manufacturer

A food and beverage manufacturer on the East Coast struggled with frequent catastrophic failures of its boiler feed water pumps. Downtime and repairs were costly, so it turned to OTC Industrial Technologies for a solution.

Zero Leaks with a New Pump for a Food and Beverage Manufacturer

A food and beverage manufacturer for several national brands was a customer of OTC, who for years had been providing service work on pumps for the manufacturer's wastewater department.

OTC's Mining Pump Booster Setup

There was an application problem at a mining site in New Mexico, and the customer reached out to TP Pump for a solution.

OTC's Pump Repair Services Help Keep the Lights On

When working with electric utilities, there's little room for error. If power plants fail, the fallout can be catastrophic. Lives are disrupted, businesses suffer, and people lose access to essential resources. OTC’s unique pump services and expertise in performing essential repairs and maintenance work are critical for plants and help keep the lights on for the people those utilities serve.

Partner with OTC Industrial Technologies for Unmatched Expertise

Talk to an OTC expert to find the right solution for your buisness.