Crimson Electric is now OTC! To streamline your ordering process and improve your customer experience we are redirecting you to OTCindustrial.com

Our Mission is to be "THE BEST" as determined by our customers. We deliver this by retaining experienced personnel, strong relationships with premier manufacturers, our location, full-service facility and years of loyal service to our customers.

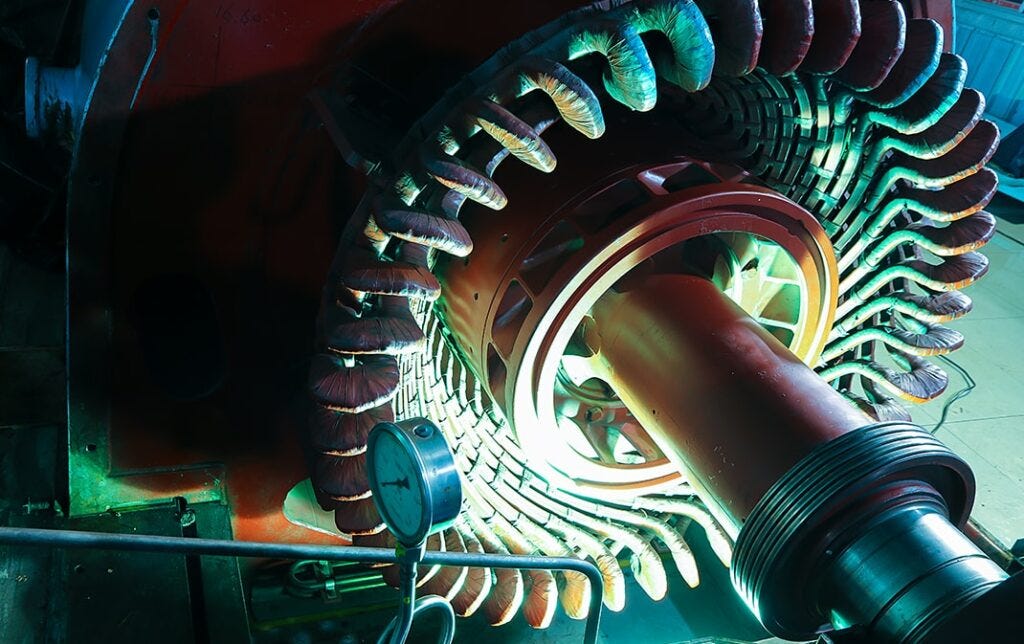

Our 16,000 square foot building area houses operations for repair and testing of AC/DC motors, servo motors, pumps and gear reducers up to 2000 HP. Our facility includes state-of-the-art equipment for the most efficient and comprehensive repairing, engineering and testing of the equipment that is crucial to your business.

Phone: 864-278-1234

Locations:

392 John Dodd Road

Spartanburg, SC 29303

Crimson Electric is now OTC! Learn how OTC can help support your business.

Services

Products

Electric Motors

Electric motors are the backbone of modern automation. They convert electrical energy into mechanical energy, and the resulting motion and torque drives the load.Motors come in all shapes and sizes and can be found in a variety of applications like industrial fans, blowers, pumps, machine tools, household appliances, power tools, disk drives, conveyors, heavy machinery, robotics, and motor vehicles.

Sprockets

A sprocket is a simple mechanical wheel with teeth or small notches which are designed to rotate and engage with the links of a chain or belt. Crimson electric carries high-quality products for a wide range of industries and applications including roller chains, conveyor chains, sprockets, cable & hose carrier systems, clutches and backstops, and continuous flex cables.

VFDs

The most common uses of a VFD are for control of fans, pumps and compressors, and these applications account for 75% of all drives operating globally. Soft starters and across-the-line contactors are other, less sophisticated types of motor controllers.

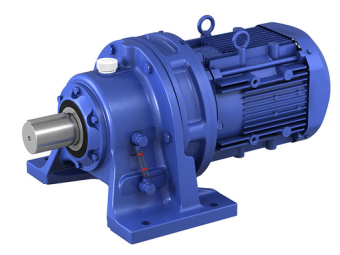

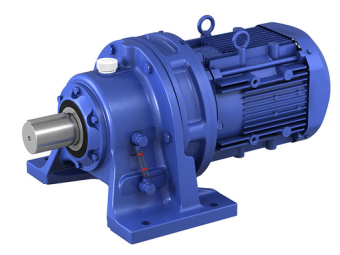

Gearmotors

In general, gearmotors function as torque multipliers and speed reducers, requiring less motor power to drive a given load. The gear housing design, the gearing type, gear lubrication, and the specific mode of integration all affect the gearmotor performance.