Viking

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary Positive Displacement Pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry—from military, to food and beverage, to chemicals, fuels and plastics—reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.

Viking offers a wide range of pump models, sizes and composition, as well as customized, fit for purpose options, to meet your strictest requirements. But, it’s not just about selecting a pump from the catalog.

Viking's application engineers would like to extend their experience in troubleshooting and product alignment to you through our liquids list below. Though this is not a complete listing of the broad range of liquids that Viking pumps can manage, this is an overview of frequent liquids. Do you have a unique application? Reach out to your local stocking distributor. We can work together to find a solution that best suits your pumping needs.

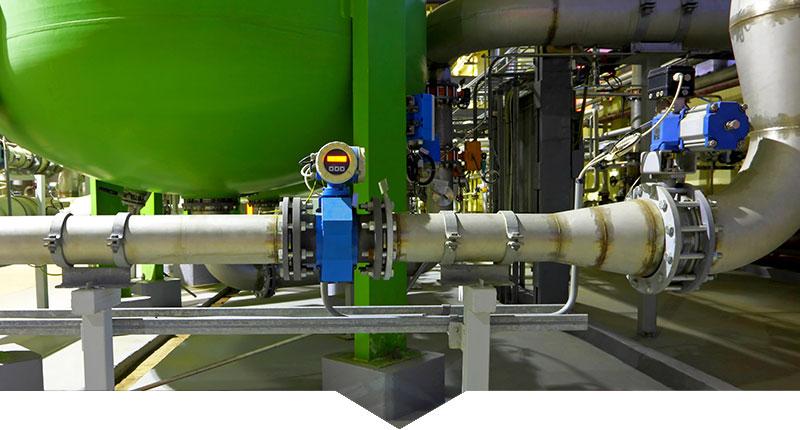

ACIDS & BASES

ADDITIVES

ADHESIVES

ALCOHOLS

AMMONIA

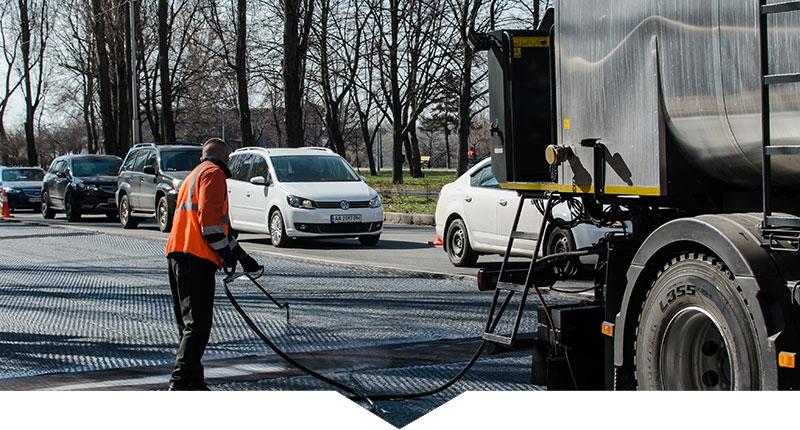

ASPHALT CEMENT

ASPHALT EMULSIONS

BIOFUELS

BLACK LIQUOR SOAP

CAULKS

CAUSTIC

CHOCOLATE

COOKING OILS

CREAMS

CRUDE OILS

DETERGENT SLURRY

DIESEL (#2 FUEL OIL)

DYES

EDIBLE OILS

ETHANOL

FILLED ASPHALT

GASOLINE

GLYCEROL/GLYCERINE

GLYCOL

GREASES

HEAT TRANSFER LIQUIDS

HIGH FRUCTOSE CORN SYRUP

HOT MELT

HOT WAX

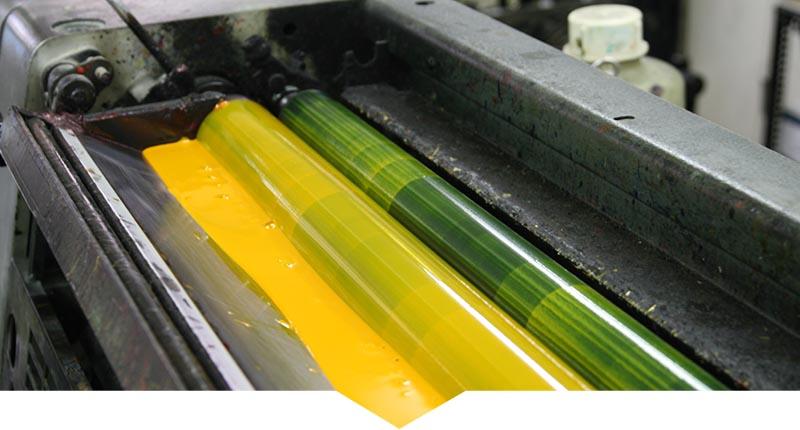

INKS

ISOCYANATE

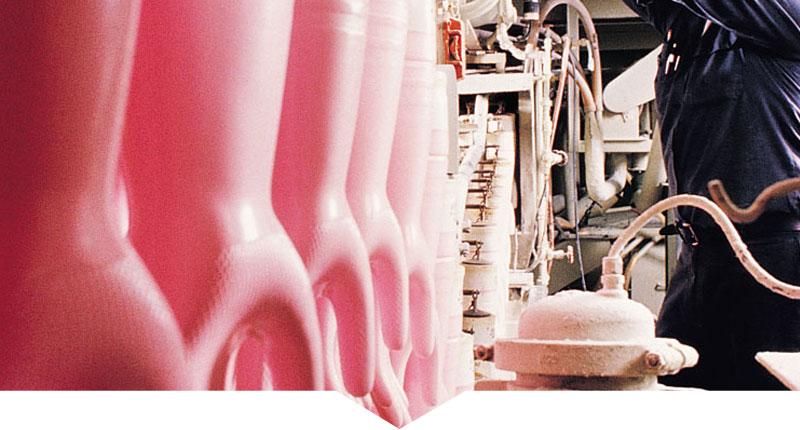

LATEX

LECITHIN

LIQUEFIED GASES

LIQUID FATS

LOTIONS

LUBE OILS

LUBE OIL BLENDING

MASSECUITE

MILL OIL

MOLASSES

MOLTEN SULFUR

PAINTS

PEANUT BUTTER

PITCH

POLYOL

POLYURETHANES

POLYVINYL ACETATE (PVAC)

QUATS

RECLAIMED ASPHALT

REFINED FUELS

RESINS

RUBBER CEMENT

SHAMPOO

SOAPS

SOLVENTS

STARCH

STARCH ADHESIVE

SUGAR MAGMA

SURFACTANTS

TALL OIL SOAP

TOOTHPASTE

TRIETHYLENE GLYCOL

WATER TREATMENT POLYMER

Parts and Kits

Parts kits provide customers with the ability to do a complete repair at once vs each time a part wears. Everything needed is in the kit, ready before you open the pump. Both seal kits and rebuild kits are available. Reduce your downtime by contacting your local stocking distributor by having a kit on your shelf ready to go when it is needed.

DESIGN: Only parts specifically designed to meet performance for pumps

QUALITY: Parts are tested to ensure optimum reliability

SUPPORT: All Genuine Parts are backed by a warranty and stocking distributor network

PARTS KITS VS. PARTIAL REPAIR

- Everything you need in one place

- Save time and money

- Increase uptime

- Increase service life

- Reduce frequency of repairs

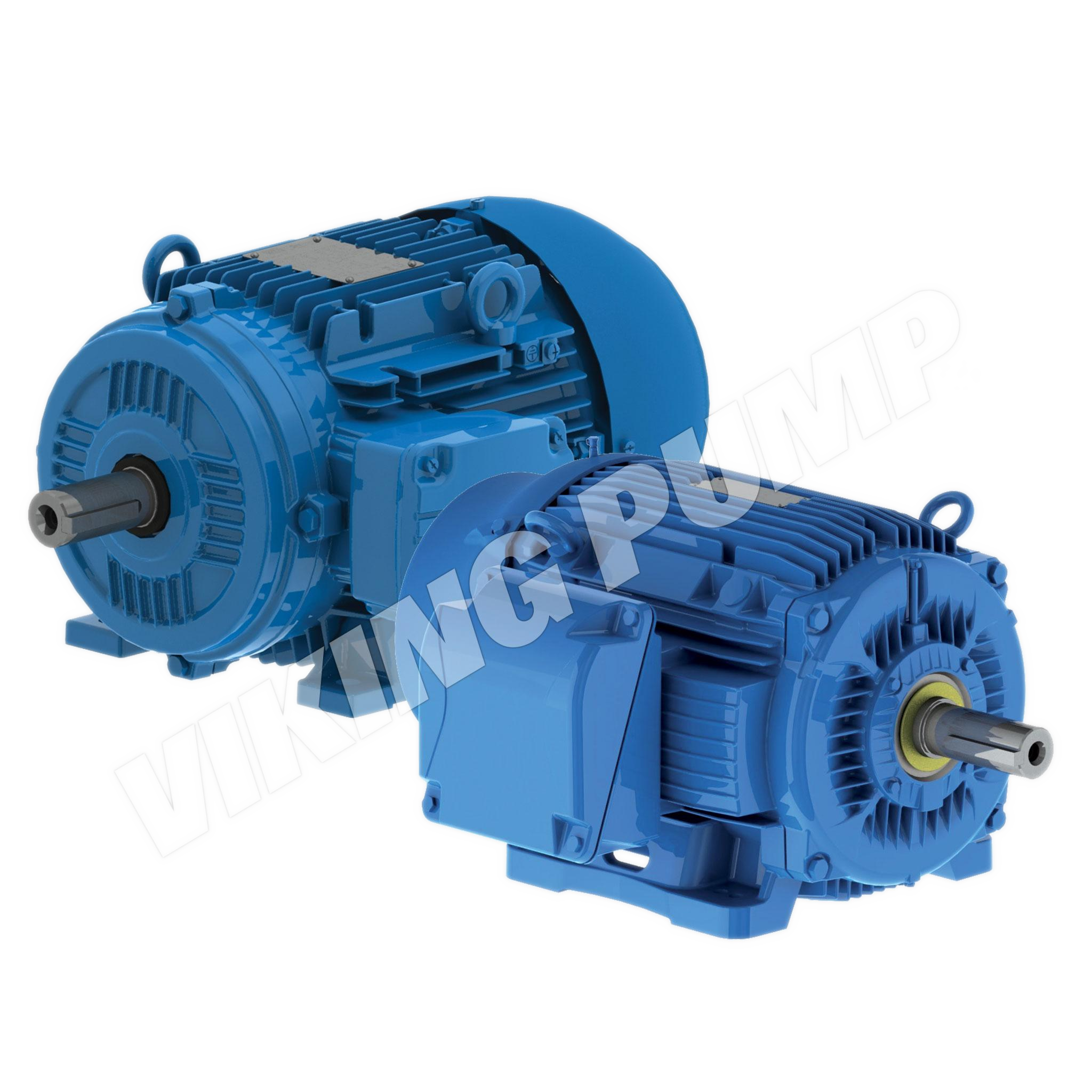

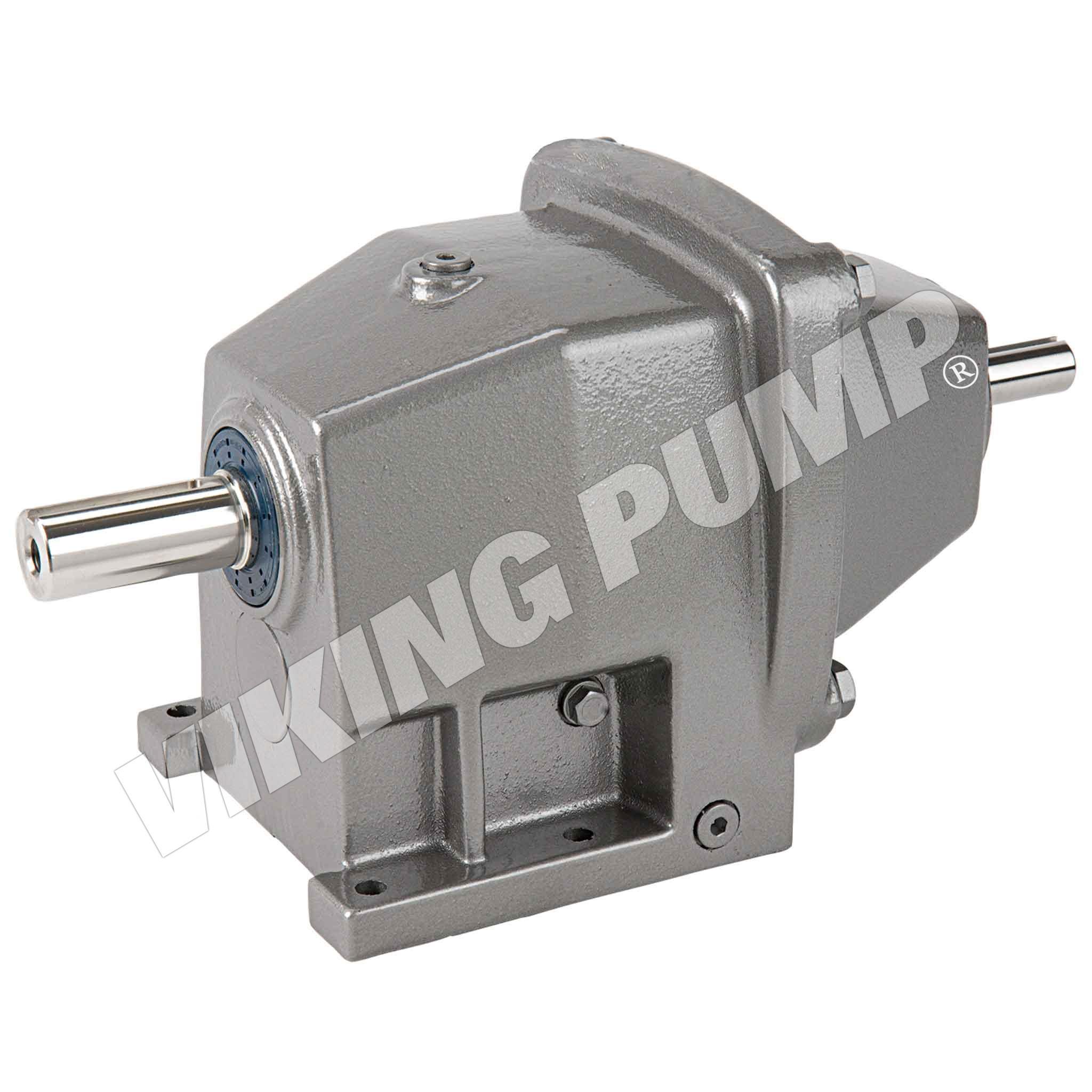

Motors

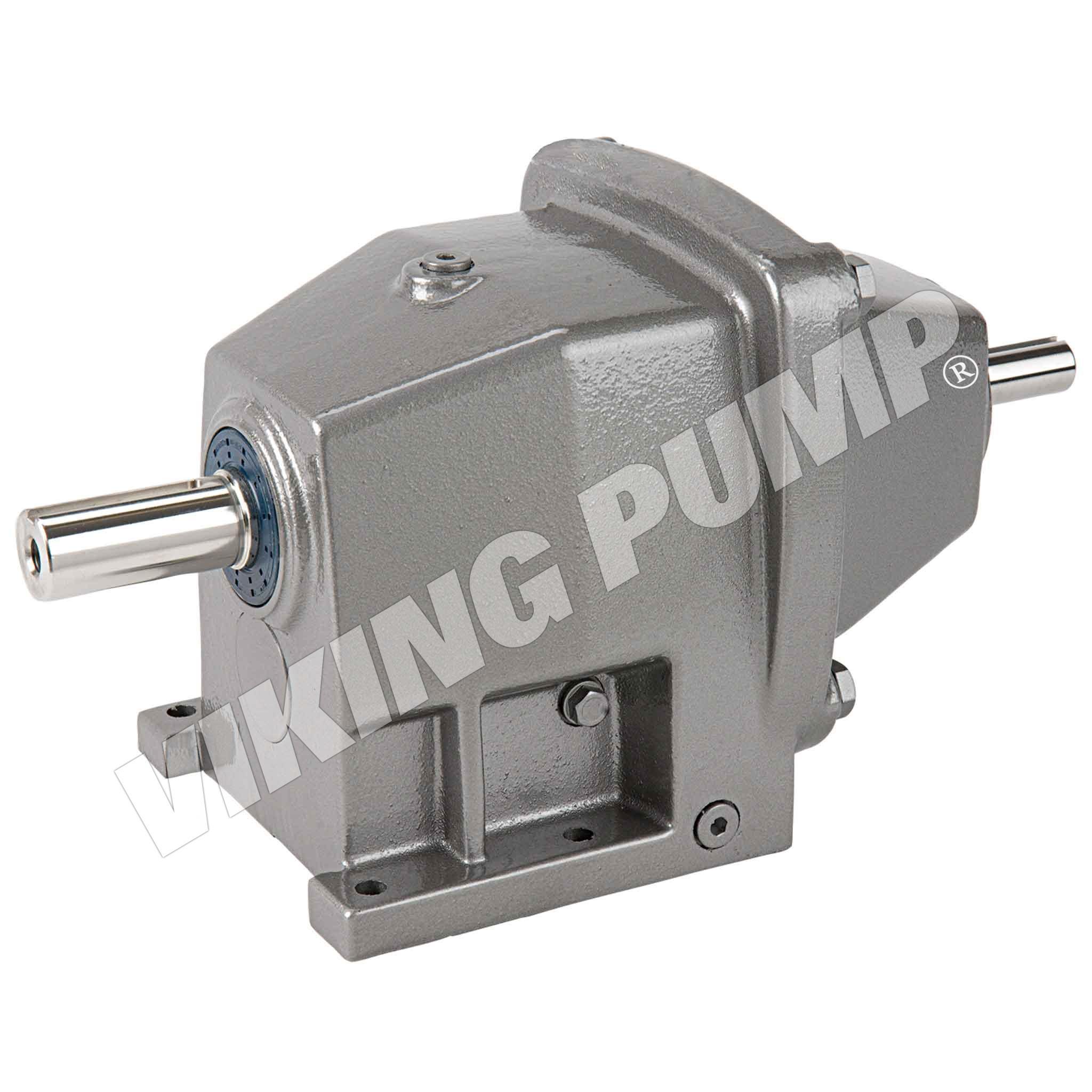

Reducers

DRIVE MOTORS

- Ease of ordering to get pump and motor from one supplier

- Competitive pricing direct through IPEG

- All major brands and types available

- Energy efficient, compliant with EISA and EC640/2009 standards

OFFSET

- Fully interchangeable ratios in each gearbox

- Multiple mounting brackets enable output shaft to match Viking shaft height

IN-LINE

- Available in multiple sizes and a variety of ratios to 350 HP / 250 kW

- Universal mounting - solid input shaft or motor mount option (IEC or NEMA)

GEAR MOTORS

- Integrated motor and reducer

- Compact footprint

Strainers

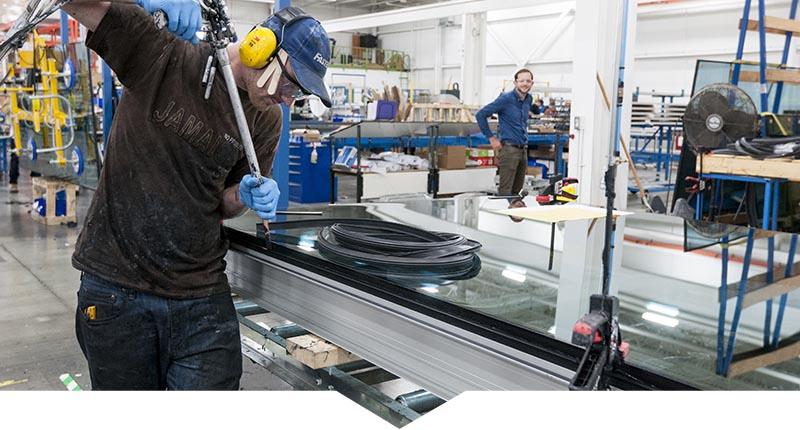

Remanufacturing

LID-EASE® STRAINERS

- Quarter-turn, easy opening breech-lock lid simplifies routine cleaning

- Inclined basket design provides low pressure drop for high system efficiency

- Top basket removal eliminates the need to drain the strainer and minimizes products loss

BOLTED-LID STRAINERS

- High quality, easy to clean simplex strainers

- Low pressure drop

- PDI ports standard (plugged)

- Lid vent standard (plugged)

- Bottom drain

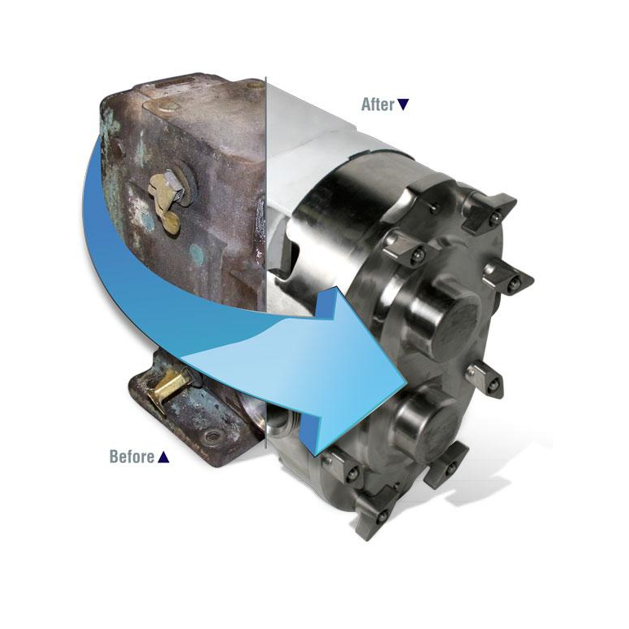

WHY REMANUFACTURE?

- Worn pump is returned to like-new condition & performance

- Your remanufactured pump carries a full 1 year factory warranty

- All remanufactured pumps are factory tested

- Save big compared to purchasing an entirely new pump

- Pumps can be remanufactured up to four times, depending on model & wear

- * For Hygienic Product Line ONLY